Erp Software For Inventory Management

Effective inventory management is crucial for businesses of all sizes, especially in today's fast-paced and competitive market. It not only ensures efficient operations but also contributes to cost savings, improved customer satisfaction, and better overall performance. To achieve these goals, many companies turn to Enterprise Resource Planning (ERP) software solutions, which offer a comprehensive approach to managing various business processes, including inventory control.

This article explores the role of ERP software in inventory management, delving into its features, benefits, and real-world applications. We will discuss how ERP systems streamline inventory operations, enhance visibility, and provide actionable insights to businesses. By understanding the capabilities and advantages of ERP for inventory management, companies can make informed decisions to optimize their operations and stay ahead in the market.

Understanding ERP and Its Role in Inventory Management

ERP software is a suite of integrated applications that businesses use to manage daily operations, including financial management, customer relationship management (CRM), supply chain management, and, importantly, inventory control. It provides a centralized platform for data storage and processing, enabling real-time access to critical information across various departments.

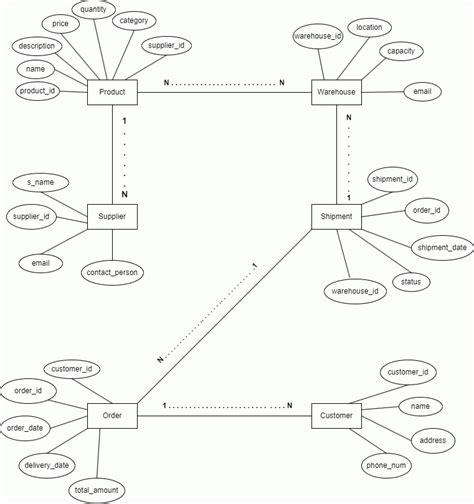

In the context of inventory management, ERP systems offer a holistic view of the entire supply chain, from procurement to warehousing to sales. They integrate various processes, such as purchase orders, receipts, adjustments, and sales, into a single platform. This integration ensures that all inventory-related data is accurate, up-to-date, and easily accessible, providing a solid foundation for effective inventory control.

Key Features of ERP for Inventory Management

- Inventory Tracking and Monitoring: ERP systems provide real-time visibility into inventory levels, allowing businesses to track stock quantities, locations, and movement. This feature helps identify overstocked or understocked items, optimize warehouse space, and reduce the risk of stockouts.

- Automated Reordering: ERP software can automate the reorder process based on predefined thresholds. When inventory levels drop below a certain point, the system automatically generates purchase orders, ensuring a consistent supply of goods without the need for manual intervention.

- Lot and Serial Number Tracking: For industries that require lot or serial number tracking, such as pharmaceuticals or electronics, ERP systems offer the ability to trace products from their origin to the end user. This feature enhances product quality control and facilitates recalls, if necessary.

- Inventory Optimization: By analyzing historical sales data and demand patterns, ERP software can optimize inventory levels, reducing carrying costs and minimizing the risk of excess inventory. This optimization ensures that businesses have the right products, in the right quantities, at the right time.

- Integration with Other Modules: One of the key advantages of ERP is its ability to integrate inventory management with other business functions. For example, integrating inventory with the sales module allows for accurate order fulfillment and real-time inventory updates, ensuring a seamless customer experience.

| Feature | Description |

|---|---|

| Real-Time Inventory Visibility | Provides up-to-date information on stock levels, locations, and movements. |

| Automated Reordering | Generates purchase orders automatically based on predefined thresholds. |

| Lot and Serial Number Tracking | Enables product traceability, enhancing quality control and recall management. |

| Inventory Optimization | Analyzes data to optimize inventory levels, reducing carrying costs and excess stock. |

| Integration with Other Modules | Integrates inventory management with other ERP functions for seamless operations. |

Benefits of ERP for Inventory Management

Implementing ERP software for inventory management brings numerous advantages to businesses, contributing to improved operational efficiency, reduced costs, and enhanced customer satisfaction.

Increased Efficiency and Accuracy

ERP systems automate many manual processes associated with inventory management, reducing the potential for human error. This automation streamlines operations, accelerates processes, and ensures accurate data, leading to improved overall efficiency.

For instance, the automated reorder feature in ERP software eliminates the need for manual stock checks and purchase order generation. This not only saves time but also reduces the likelihood of errors, such as incorrect quantities or outdated prices.

Improved Decision Making

ERP software provides businesses with valuable insights and analytics, enabling data-driven decision-making. By analyzing historical data, sales trends, and customer behavior, companies can make informed choices about inventory levels, product mix, and procurement strategies.

For example, the inventory optimization feature in ERP can help identify slow-moving or obsolete stock, allowing businesses to adjust their inventory accordingly. This not only frees up warehouse space but also reduces the risk of financial losses due to excess inventory.

Enhanced Customer Service

Effective inventory management is critical to providing excellent customer service. ERP software ensures that businesses have accurate and up-to-date information on stock availability, allowing them to fulfill orders promptly and accurately.

By integrating inventory management with the sales module, ERP systems enable real-time inventory updates during the sales process. This ensures that customers receive accurate information about product availability, preventing overselling and enhancing the overall customer experience.

Cost Savings

Implementing ERP for inventory management can lead to significant cost savings for businesses. By optimizing inventory levels, reducing excess stock, and minimizing carrying costs, companies can improve their bottom line.

Additionally, the automated reorder feature in ERP can help negotiate better pricing with suppliers, as it allows for bulk purchases and timely replenishment. This not only reduces procurement costs but also strengthens supplier relationships.

| Benefit | Description |

|---|---|

| Increased Efficiency | Automates processes, reducing manual errors and streamlining operations. |

| Improved Decision Making | Provides data-driven insights for informed inventory and procurement strategies. |

| Enhanced Customer Service | Ensures accurate and timely order fulfillment, improving customer satisfaction. |

| Cost Savings | Optimizes inventory levels, reduces carrying costs, and facilitates better supplier negotiations. |

Choosing the Right ERP for Inventory Management

When selecting an ERP solution for inventory management, businesses should consider several key factors to ensure the system meets their specific needs and requirements.

Scalability and Flexibility

Choose an ERP system that can scale with your business as it grows and evolves. Look for flexibility in terms of customization and configuration options to adapt the software to your unique inventory management processes and strategies.

Integration Capabilities

Ensure that the ERP system integrates seamlessly with your existing business applications and systems. This is particularly important for inventory management, as it should be able to exchange data with financial, sales, and procurement modules without disruptions.

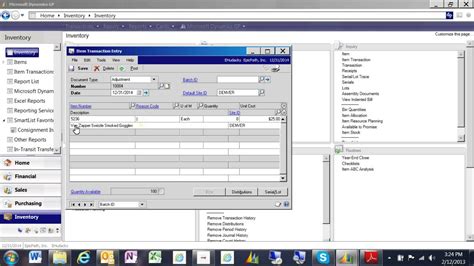

User-Friendly Interface

A user-friendly interface is crucial for efficient and effective use of the ERP system. Look for a platform that is intuitive, easy to navigate, and provides clear instructions and feedback to users, reducing the learning curve and improving adoption rates.

Security and Data Protection

Inventory management involves sensitive data, including product details, supplier information, and financial records. Ensure that the ERP system has robust security measures in place to protect this data from unauthorized access, theft, or loss. This includes encryption, access controls, and regular security audits.

Support and Training

Consider the level of support and training provided by the ERP vendor. Look for vendors who offer comprehensive training programs to ensure your staff can use the system effectively. Additionally, choose a vendor with a strong reputation for customer support, as this can be crucial during the implementation and post-launch phases.

| Consideration | Description |

|---|---|

| Scalability and Flexibility | Choose an ERP that can scale with your business and offers customization options. |

| Integration Capabilities | Ensure seamless integration with existing business applications and systems. |

| User-Friendly Interface | Select an ERP with an intuitive and easy-to-use interface for better adoption. |

| Security and Data Protection | Ensure robust security measures to protect sensitive inventory data. |

| Support and Training | Opt for vendors who provide comprehensive support and training programs. |

Real-World Applications and Success Stories

ERP software has been successfully implemented in various industries to streamline inventory management and drive business growth. Here are some real-world examples of how ERP has transformed inventory operations:

Retail Industry

A large retail chain implemented ERP for inventory management, integrating it with their point-of-sale (POS) system. The ERP system provided real-time visibility into stock levels across all stores, allowing for better inventory planning and allocation. This resulted in a 15% increase in sales and a significant reduction in stockouts, leading to improved customer satisfaction.

Manufacturing Sector

A manufacturing company used ERP to manage their complex supply chain, including inventory control. The ERP system’s lot and serial number tracking feature helped them trace products from raw materials to finished goods, enhancing quality control and facilitating recalls. Additionally, the system’s inventory optimization capabilities reduced excess stock by 20%, leading to substantial cost savings.

E-commerce Business

An online retailer implemented ERP to manage their rapidly growing inventory, which included thousands of SKUs. The ERP system automated the reorder process, ensuring a consistent supply of products. By integrating inventory management with their website, the company achieved real-time inventory updates, preventing overselling and improving customer trust.

Healthcare Industry

A hospital network implemented ERP for inventory management of medical supplies and pharmaceuticals. The system’s automated reordering feature helped ensure a steady supply of critical items, reducing the risk of shortages. Additionally, the ERP system’s lot tracking feature facilitated product recalls, enhancing patient safety and compliance with regulatory standards.

Future Trends and Implications

The future of ERP for inventory management is promising, with several emerging trends and technologies set to revolutionize the way businesses manage their inventory.

Artificial Intelligence and Machine Learning

AI and machine learning technologies are expected to play a significant role in ERP systems, particularly in inventory management. These technologies can analyze vast amounts of data, including sales patterns, customer behavior, and market trends, to provide accurate forecasts and optimize inventory levels.

Cloud-Based ERP

Cloud-based ERP solutions are becoming increasingly popular, offering businesses greater flexibility, scalability, and cost-effectiveness. Cloud ERP for inventory management provides real-time access to inventory data from anywhere, enhancing collaboration and decision-making, especially for businesses with distributed operations.

Integration with Internet of Things (IoT)

The integration of ERP with IoT devices and sensors can provide real-time data on inventory levels, product movements, and environmental conditions. This data can be used to optimize inventory management, improve supply chain efficiency, and reduce costs.

Blockchain for Traceability

Blockchain technology can enhance the traceability and security of inventory data. By recording inventory transactions on a distributed ledger, blockchain can provide an immutable record of product movements, ensuring transparency and trust in the supply chain.

Predictive Analytics

Predictive analytics in ERP systems can forecast demand, identify trends, and optimize inventory levels. By analyzing historical data and considering various factors, such as seasonality and market fluctuations, predictive analytics can help businesses make proactive inventory management decisions.

| Future Trend | Description |

|---|---|

| AI and Machine Learning | Analyzing data for accurate forecasts and inventory optimization. |

| Cloud-Based ERP | Offering flexibility, scalability, and real-time access to inventory data. |

| Integration with IoT | Providing real-time inventory data and enhancing supply chain efficiency. |

| Blockchain for Traceability | Ensuring transparency and security of inventory transactions. |

| Predictive Analytics | Forecasting demand and optimizing inventory levels proactively. |

Conclusion

ERP software has emerged as a powerful tool for inventory management, offering businesses a comprehensive solution to streamline operations, enhance visibility, and improve decision-making. By implementing ERP, companies can achieve increased efficiency, reduced costs, and improved customer satisfaction, all of which are crucial for long-term success and competitiveness in today’s market.

As we look to the future, the integration of emerging technologies with ERP systems promises even greater benefits for inventory management. Businesses that embrace these digital transformations and leverage the capabilities of ERP will be well-positioned to stay ahead in a rapidly evolving market landscape.

How does ERP software integrate with existing business systems?

+

ERP software is designed to integrate seamlessly with existing business systems, such as financial management, CRM, and procurement software. This integration ensures that data is shared and updated across different departments and systems, providing a holistic view of the business operations.

What are the key benefits of using ERP for inventory management?

+

ERP offers several key benefits for inventory management, including increased efficiency through automation, improved decision-making with data-driven insights, enhanced customer service with accurate order fulfillment, and cost savings through optimized inventory levels and reduced carrying costs.

Can ERP software handle complex inventory scenarios, such as multiple warehouses or international supply chains?

+

Yes, ERP software is designed to manage complex inventory scenarios, including multiple warehouses, international supply chains, and diverse product portfolios. It provides a centralized platform for managing inventory data, ensuring accurate tracking and control, regardless of the scale or complexity of the operation.