Enterprise Inventory Management

In today's fast-paced and dynamic business landscape, effective inventory management is crucial for enterprises to thrive and stay competitive. The complexities of managing large-scale operations, multiple product lines, and diverse supply chains require a sophisticated approach to inventory optimization. This article delves into the world of enterprise inventory management, exploring its challenges, best practices, and innovative solutions.

The Challenges of Enterprise Inventory Management

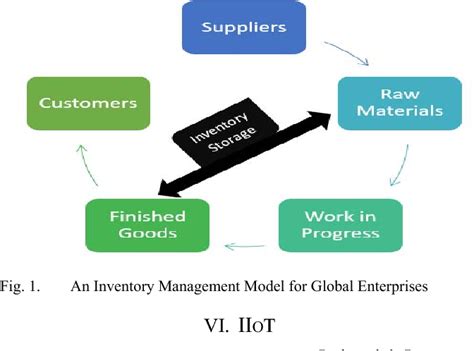

Enterprise inventory management presents a unique set of challenges that differ from those faced by smaller businesses. With a larger scale of operations, enterprises must grapple with intricate supply chains, extensive product portfolios, and diverse customer demands. Here are some key challenges that enterprises encounter:

Complex Supply Chains

Enterprises often operate within intricate supply chains that span across multiple countries and involve numerous suppliers, manufacturers, and distributors. Managing these complex networks requires a robust system to track inventory movements, monitor lead times, and ensure product availability.

Diverse Product Lines

Large enterprises typically offer a wide range of products, each with its own unique characteristics, shelf life, and demand patterns. Effectively managing such diversity requires sophisticated categorization, accurate forecasting, and efficient inventory allocation strategies.

Seasonal and Dynamic Demand

Enterprises must navigate the challenges of fluctuating demand, especially during peak seasons or unexpected market shifts. Accurate demand forecasting and flexible inventory planning are essential to avoid stockouts or excess inventory.

Regulatory and Compliance Issues

Enterprise inventory management also involves navigating a complex web of regulations and compliance standards, particularly in industries such as pharmaceuticals, food and beverage, and electronics. Ensuring adherence to these regulations adds an extra layer of complexity to inventory management processes.

Best Practices for Enterprise Inventory Management

To overcome the challenges mentioned above, enterprises can adopt best practices that streamline inventory management and optimize their operations. Here are some key strategies:

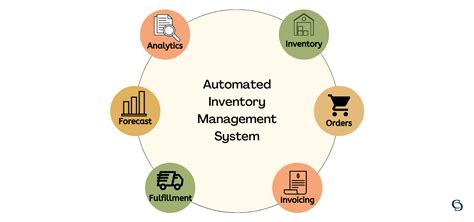

Implement Advanced Inventory Management Software

Utilizing advanced inventory management software solutions is a cornerstone of effective enterprise inventory management. These systems offer real-time visibility into inventory levels, automate critical processes, and provide actionable insights for informed decision-making. With features like barcode scanning, lot tracking, and predictive analytics, enterprises can enhance efficiency and accuracy.

Strategic Inventory Placement

Enterprises should strategically place inventory across their distribution network to minimize transportation costs and reduce lead times. By optimizing stock levels at various warehouses and distribution centers, businesses can improve order fulfillment efficiency and enhance customer satisfaction.

Accurate Demand Forecasting

Accurate demand forecasting is vital for effective inventory planning. Enterprises should leverage historical data, market trends, and advanced analytics tools to predict demand patterns accurately. This enables businesses to align inventory levels with customer demand, reducing the risk of stockouts or excess inventory.

Efficient Inventory Optimization Techniques

Enterprises can employ various optimization techniques to streamline inventory management. These include just-in-time (JIT) inventory management, which focuses on minimizing inventory levels while ensuring timely availability, and economic order quantity (EOQ) calculations, which help determine the optimal order quantity to minimize holding costs.

Supplier Collaboration

Enterprises should foster strong relationships with suppliers to improve inventory management. Collaborative efforts can lead to more accurate lead time estimates, streamlined procurement processes, and better visibility into supply chain disruptions. This collaboration can also facilitate the implementation of vendor-managed inventory (VMI) programs, where suppliers proactively manage inventory levels based on enterprise demand signals.

Innovative Solutions for Enterprise Inventory Management

As technology advances, innovative solutions are emerging to revolutionize enterprise inventory management. Here are some cutting-edge approaches:

Internet of Things (IoT) and RFID Technology

The integration of IoT and RFID (Radio-Frequency Identification) technology enables real-time tracking of inventory across the supply chain. Enterprises can automate inventory tracking, receive real-time updates on stock levels, and improve overall visibility, leading to more efficient inventory management.

Blockchain for Supply Chain Transparency

Blockchain technology offers a secure and transparent way to manage inventory across the supply chain. By creating an immutable record of transactions, enterprises can track inventory movements, ensure product authenticity, and enhance supply chain efficiency. Blockchain also facilitates better collaboration among supply chain partners.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms can analyze vast amounts of data to optimize inventory levels, forecast demand, and identify patterns that may impact inventory management. These technologies can automate routine tasks, enhance decision-making, and improve overall inventory management efficiency.

Cloud-Based Inventory Management Systems

Cloud-based inventory management systems offer scalability, flexibility, and real-time data access. Enterprises can leverage these systems to manage inventory across multiple locations, collaborate with supply chain partners, and access critical inventory information from anywhere, at any time.

Data Analytics for Informed Decision-Making

Enterprises should embrace data analytics to gain deeper insights into their inventory management processes. By analyzing historical data, enterprises can identify trends, optimize inventory levels, and make data-driven decisions to improve overall inventory efficiency and reduce costs.

Performance Analysis and Key Metrics

To assess the effectiveness of enterprise inventory management strategies, businesses should track and analyze key performance indicators (KPIs). Here are some essential metrics to consider:

| Metric | Description |

|---|---|

| Inventory Turnover Ratio | Measures how quickly inventory is sold and replaced. A higher ratio indicates better inventory management and reduced carrying costs. |

| Days Sales of Inventory (DSI) | Indicates the average number of days it takes to sell the current inventory. Lower DSI values reflect efficient inventory management. |

| Stockout Rate | Measures the percentage of orders that cannot be fulfilled due to stockouts. A low stockout rate indicates effective inventory planning. |

| Inventory Accuracy | Assesses the accuracy of recorded inventory levels compared to physical counts. High accuracy ensures reliable inventory data. |

| Lead Time | Measures the time taken to deliver products from the supplier to the customer. Shorter lead times improve customer satisfaction. |

Conclusion

Effective enterprise inventory management is a critical success factor for businesses operating at scale. By embracing best practices, leveraging innovative technologies, and staying agile, enterprises can optimize their inventory management processes, reduce costs, and enhance overall operational efficiency. As the business landscape continues to evolve, enterprises must remain proactive in their inventory management strategies to maintain a competitive edge.

FAQ

How can enterprises improve their inventory management processes without disrupting ongoing operations?

+

Enterprises can adopt a phased approach to implementing inventory management improvements. This involves identifying critical areas for enhancement, such as accurate demand forecasting or supplier collaboration, and gradually rolling out changes to minimize disruption. Additionally, utilizing robust inventory management software with comprehensive training and support can ensure a smooth transition.

What are the potential risks of relying solely on AI and machine learning for inventory management decisions?

+

While AI and machine learning offer significant benefits, there are potential risks to consider. Over-reliance on these technologies without proper human oversight can lead to unexpected errors or biases in decision-making. It’s crucial to have robust data governance practices, regular audits, and human intervention to ensure accurate and ethical inventory management.

How can enterprises ensure the security and privacy of their inventory data when using cloud-based systems?

+

Enterprises should prioritize data security and privacy when adopting cloud-based inventory management systems. This involves selecting reputable cloud service providers with strong security measures, implementing access controls and encryption protocols, and regularly conducting security audits. Additionally, enterprises should ensure compliance with relevant data protection regulations.